Worn equipment is inefficient and can produce inaccurate results, ultimately delaying critical work.

So, while it might be tempting to replace your lab equipment as soon as it shows signs of wear, it isn’t your only option. Often, the source of an issue in chromatography equipment is one part that can be easily replaced.

This is where reconditioned parts come into play. These parts are cheaper than original equipment manufacturer (OEM) parts, having been repaired or inspected by a skilled engineer to ensure quality and performance.

Below, we’ve pulled together some of the key benefits of reconditioned parts, and why you should consider choosing them over parts from the manufacturer.

Choosing a reconditioned part means paying a much lower cost, compared to purchasing new parts from the manufacturer or having to replace your equipment. In fact, most reconditioned parts are up to 70% cheaper than parts bought directly from the manufacturer.

This cost reduction is because second-hand parts are usually recovered from equipment that is no longer used, such as when a lab is closed or from an exchange programme.

By freeing up these costs, it allows you to spend in other areas of your laboratory operations.

Replacing broken parts when you spot a fault is a simple and effective way to keep your laboratory working accurately for longer. It allows your lab to get the most out of its equipment, while improving the value of the initial investment.

Plus, as technology evolves, replacing parts ensures existing equipment can stay up to date with new developments, without the need to purchase expensive new equipment.

One of the benefits of preventative maintenance is that an engineer will suggest whether parts need replacing, helping you to ensure your lab equipment continues working effectively.

At LC Services, our service plans include preventative maintenance, with our expert technicians able to replace parts, if needed.

Refurbished parts come with a low buy-risk, as they provide the same durability and performance as new components but cost far less. Because of this, the value of the part or equipment will depreciate less compared to buying new.

If you also need to resell the item within the next year, the resale cost will stay steady.

A common misconception is that because refurbished parts are cheaper, they aren’t to the same high standard as an original equipment manufacturer.

The engineers at LC Services work hard to give refurbished chromatography parts a thorough examination, making the necessary repairs to get them back to peak performance.

We’re so confident in the quality of our reconditioned parts, we offer a six month warranty on all parts.

By using reconditioned parts, you will not only help the environment, but your lab will be more sustainable and meet environmental goals. You’ll also be disposing of a single component, rather than an entire piece of equipment.

Plus, reconditioned parts are upcycled from unwanted equipment and faulty parts, meaning less waste is sent to landfill, over buying directly from the manufacturer.

The turnaround time for original equipment manufacturer parts often has long lead times, with these sometimes being up to six weeks. Waiting this amount can cause extended periods of downtime for your lab and can negatively impact lab productivity.

However, by choosing refurbished parts, such as from LC Services, you can expect fast delivery, with stocked parts arriving to you in less than a week when shipped to labs worldwide.

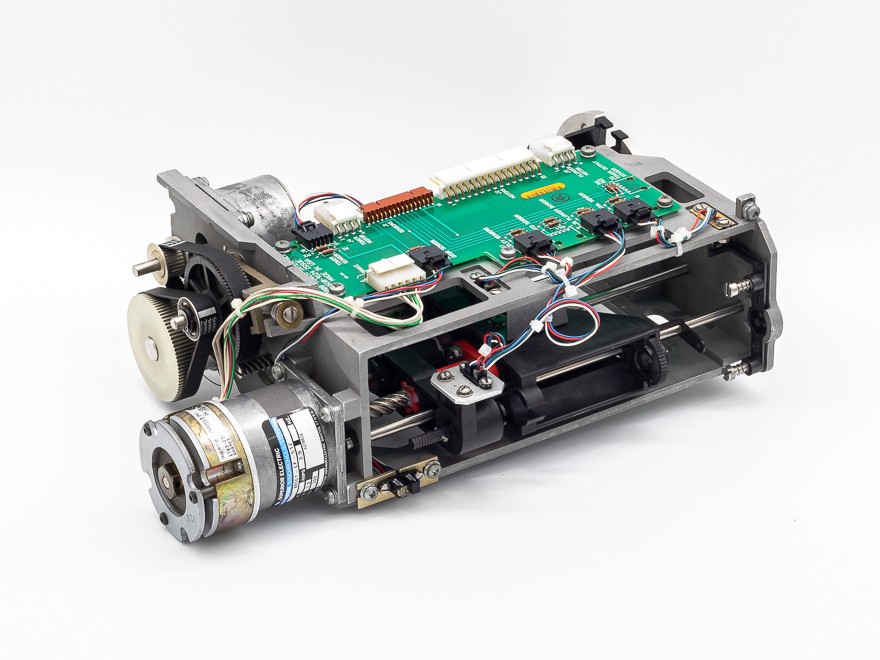

(Refurbished Perkin Eelmer Clarus XL Injector Tower)

(Refurbished Perkin Eelmer Clarus XL Injector Tower)The LC Services exchanged parts programme means you can purchase a reconditioned part at a discounted exchange price, allowing you to send your faulty part to us within four weeks.

If the item is in stock, we can ship the same day prior to your return of the faulty part. If your item isn’t in stock, we can also provide a refurbishment of your defective part. Our technicians will refurbish and return it to you at the exchange price.

Find out more about how our exchange parts programme works: https://www.lcservicesltd.co.uk/reconditioned-parts-exchange/

If you are finding broken equipment and inaccurate results frequently in your lab, it could be time to consider preventative maintenance.

Preventative maintenance highlights potential problems with lab equipment, allowing them to be rectified before they become too costly.

For your chromatography equipment to work at its best, it should be maintained at least once per year, with preventative maintenance also helping to:

You can read more about this in our benefits of preventative maintenance blog.

At LC Services, we offer preventative maintenance in three of our service, maintenance, repairs and support plans. This is delivered by our team of highly-qualified engineers and is included from plan 2 upwards.

Throughout your service plan with us, you’ll have ongoing support from one of our certified engineers. This support is available over the phone and onsite.

If needed, our engineers can even perform an Operational Qualification (also called OQ), for equipment which isn’t working as well as it should or has recently been replaced. Our OQs can be added to any preventative maintenance plan and provide you with a certificate for peace of mind.

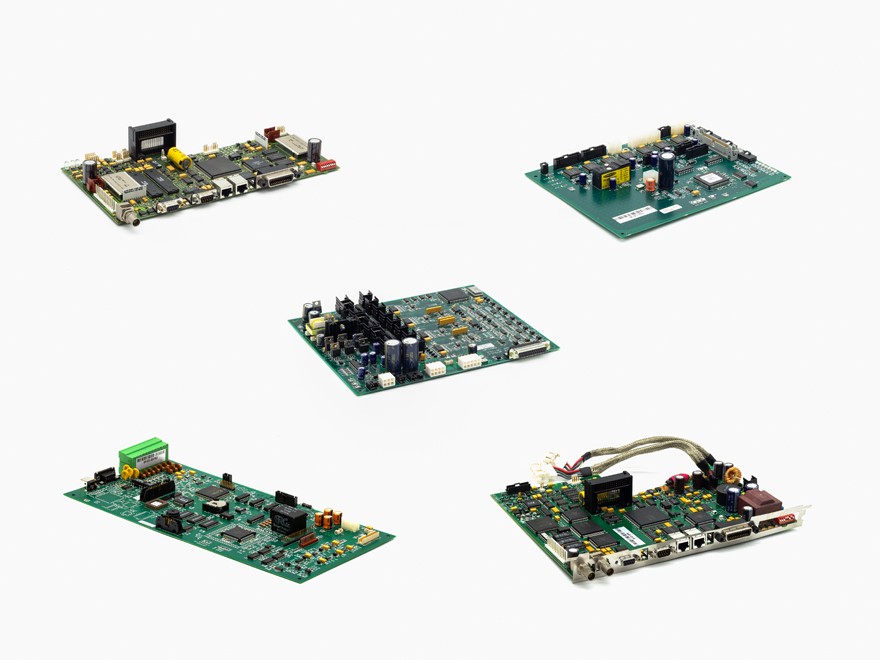

(Refurbished Power Control Boards)

(Refurbished Power Control Boards)LC Services have been supplying reconditioned parts and servicing chromatography equipment for over 30 years.

All of our reconditioned parts are tested and repaired by our highly experienced team. If you purchase from us through our refurbished and exchanged parts programme, each part will also come with a six-month warranty. Both of which are available worldwide.

To learn more about our reconditioned and exchanged parts programme, be sure to download our brochure below, which contains further information.

If you have any further questions about our reconditioned or exchanged parts programme, please get in touch.